1. Preparation Work

- Prepare pipes of the appropriate material and size according to processing requirements, clean any surface impurities and dirt.

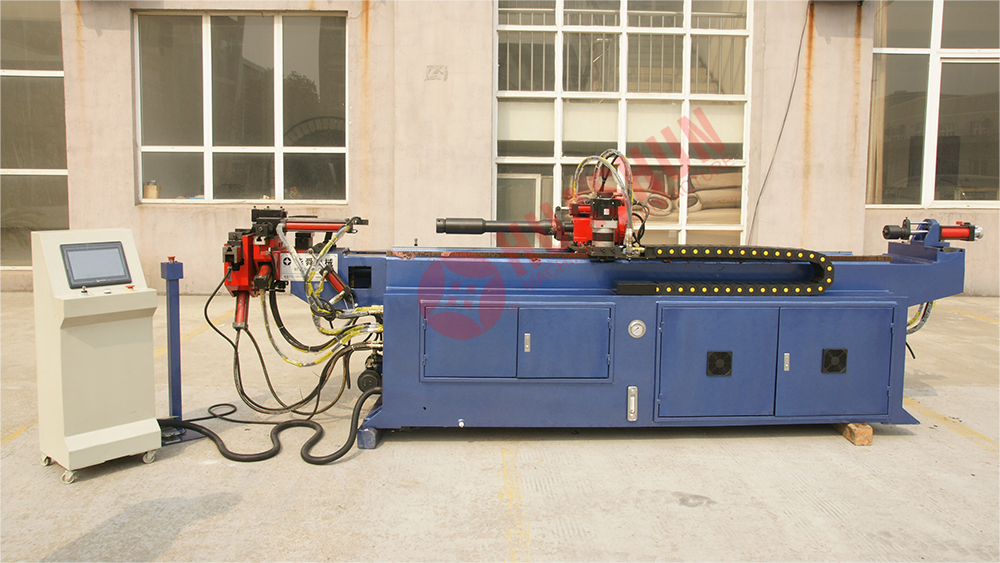

- In this case, we are using the Huashun SB-38CNC2A1S. Check the status of the pipe(tube) bending machine, ensuring stability, adequate hydraulic pressure, and proper functioning of the electrical system.

- Install the molds, ensuring they are securely mounted and parallel to the machine frame.

- Setting/Adjusting Parameters,on SB-38CNC-2A1S

2. Confirm that the dimensions of the clamps and molds match the pipe diameter.

- Ensure that the molds on the bending machine are suitable for the specified bending radius.

- Set the parameters for two bends, with each bend at an angle of 90° according to the product’s bending requirements.

- Input the total pipe length, which includes the lengths of 3 straight sections and 2 bending sections.

- Set the distances between the pipe's origin (A) and the first bend (B), and between the first bend (B) and the second bend (C). Also, adjust the rebound amount accordingly.

- Adjust the bending speed to a suitable level to avoid deformation based on the material and diameter of the pipe.

- Adjust the appropriate pressure and torque settings to ensure uniform bending of the pipe.

Our engineers will set and debug all parameters and programs based on the data provided during the custom product process. If you need to reset or modify parameters, the Huashun Machinery after-sales team will provide free technical service and support.

3. Placing the Pipe

- Place the pipe in the mold, ensuring alignment with the mold.

- Secure the pipe with clamps to prevent movement or twisting during the bending process.

4. Starting the Bending

- Start the tube bending machine.

- Use the control panel buttons or foot pedal to adjust the machine’s operating speed and direction as needed.

5.Precautions:

- Wear appropriate safety protective gear during operation.

- Check parameters and ensure they are correctly set before starting the machine to avoid unnecessary errors.

- Handle materials carefully, keeping them clean and lubricated, or use core material assistance to reduce pipe deformation.

Handle materials carefully, keeping them clean and lubricated, or use core material assistance to reduce pipe deformation.